Swap Guide: Hydro-Boost Brake Upgrade for Coyote-Swapped 65–70 Mustangs & 67–70 Cougars

Transform Your Classic Ford’s Braking Performance with the Stang-Aholics Hydro-Boost Kit

If you’re upgrading your classic 1965–70 Mustang or 1967–70 Cougar with a modern 5.0L Coyote engine, you already know how much power and reliability this swap brings. But there’s one part of the build that often gets overlooked — the braking system.

The Coyote engine’s wide architecture and low vacuum make it difficult to retain a traditional vacuum-assisted booster. That’s where the Hydro-Boost Power Brake System from Stang-Aholics comes in. This purpose-built kit provides modern hydraulic brake assist, improved pedal feel, and easy packaging for tight engine bays.

Why Upgrade to a Hydro-Boost Brake System?

A Hydro-Boost system uses hydraulic pressure from your power steering pump rather than engine vacuum to assist braking. This makes it the ideal upgrade for performance builds and engine swaps where vacuum is limited — like the 5.0L Coyote.

Reliable Brake Assist at Any RPM

Unlike a vacuum booster, hydro-boost delivers consistent assist even at idle or wide-open throttle. That means strong, confident braking every time — perfect for track days or spirited canyon drives.

Compact Design for Tight Engine Bays

The Coyote’s DOHC heads and front accessory drive leave little room for a traditional vacuum booster. The Stang-Aholics Hydro-Boost unit is smaller in diameter, giving you the clearance you need near the firewall, master cylinder, and hood hinges.

Higher Pressure = Better Stopping Power

A hydro-boost system typically delivers up to 2,000 PSI of hydraulic pressure, nearly double that of a vacuum booster. The result? Shorter stopping distances and a firmer, more responsive brake pedal.

OEM-Quality Reliability

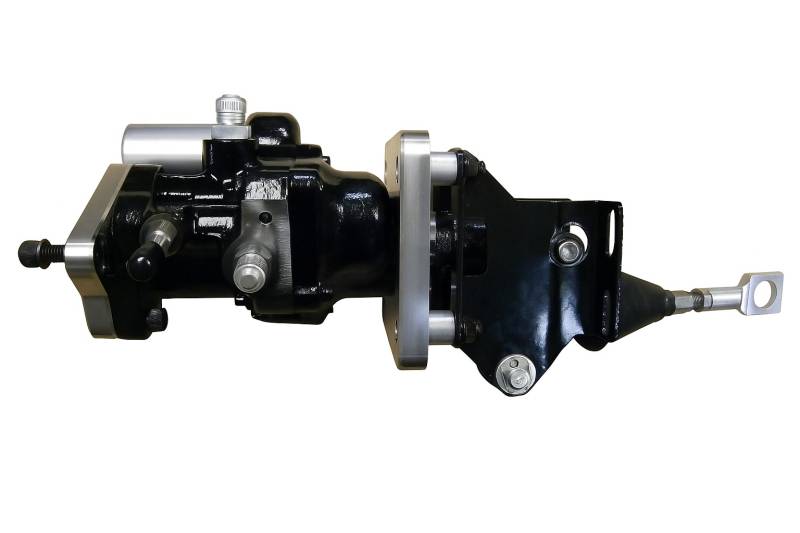

The Stang-Aholics kit uses an all-new Bosch Hydro-Boost unit and CNC-machined billet aluminum brackets, ensuring long-term durability and a factory-like fit.

Inside the Stang-Aholics Supplied Hydro-Boost Kit

We offer multiple kits depending on your Mustang year. One is engineered specifically for 1965–66 Mustangs, and another for the 1967-70 Mustangs and 1967–70 Cougars all designed with the Coyote or modular engine swaps in mind.

Key Kit Highlights:

-

Genuine Bosch Hydro-Boost unit – new, not remanufactured

-

Billet T6061 aluminum brackets – precision CNC machined

-

Cantilever design for Modular Engine head clearances

-

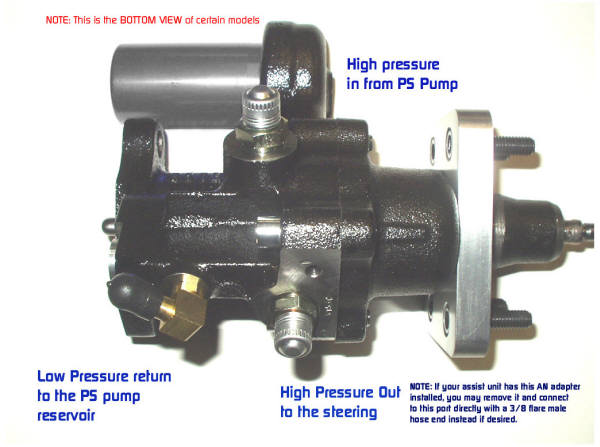

Pre-installed AN-6 fittings for high-pressure lines

-

Works well with the Wilwood master cylinders (Baer Master Cylinders also available) and optional proportioning/distribution combination valves

-

Includes detailed installation instructions and telephone technical support

Pro Tip: The kit can be combined with Stang-Aholics’ braided hose/fitting set and Wilwood master cylinder with combination valve for a more complete and less hassle installation.

Installation Overview

Step 1: Prepare the Firewall

Remove your stock booster and drill mounting holes using the provided template. Classic Mustang applications require stock hood spring removal or a prop rod for clearance. We can also supply billet aluminum hood hinges with gas struts that will clear the unit.

Step 2: Mount the Hydro-Boost and Master Cylinder

Bolt the Hydro-Boost unit to the Stang-Aholics bracket and connect the pushrod to your brake pedal. Mount the Wilwood master cylinder and confirm proper pedal travel.

Step 3: Route Hydraulic Lines

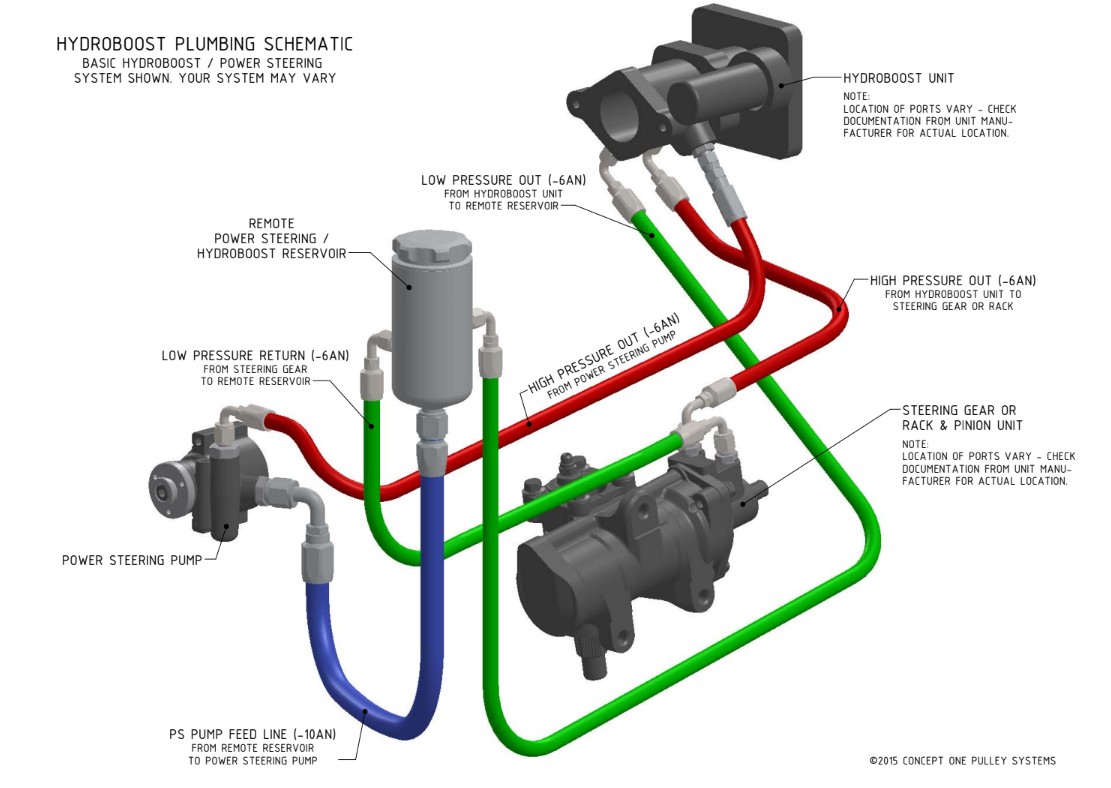

Hydraulic Flow Path Diagram

Use AN-6 braided lines rated for at least 2,500 PSI. Return both the Hydro-Boost and Steering Box lines to the pump reservoir via a “T" fitting, or you can use a Remote Reservoir with TWO Return fittings designed for hydroboost pump applications.

Step 4: Connect Brake Plumbing

Connect your master cylinder to a proportioning or combination valve. Bleed the brakes (RR → LR → RF → LF) and hydraulic system thoroughly to remove air.

Real-World Results

Builders report dramatic improvements in braking feel and consistency with this system:

“The Hydro-Boost gave my ’66 Coyote swap modern-car braking — no vacuum issues, no fade, just perfect control.”

— Mike, Restomod Mustang Builder

Conclusion: The Smart Brake Upgrade for Your Coyote Swap

When you modernize your classic Mustang or Cougar with a 5.0 Coyote engine swap, you need brakes that can keep up. The Stang-Aholics Hydro-Boost Power Brake Kit delivers modern stopping power, reliable hydraulic assist, and a clean fit in tight engine bays.

Whether you’re daily driving your restomod or building a weekend track car, this Hydro-Boost system brings the confidence and control of a late-model Mustang to your vintage classic — all without sacrificing originality or under-hood style.

Learn more or order your kit here:

Stang-Aholics Hydro-Boost Power Brake Assembly

Additional Image Gallery:

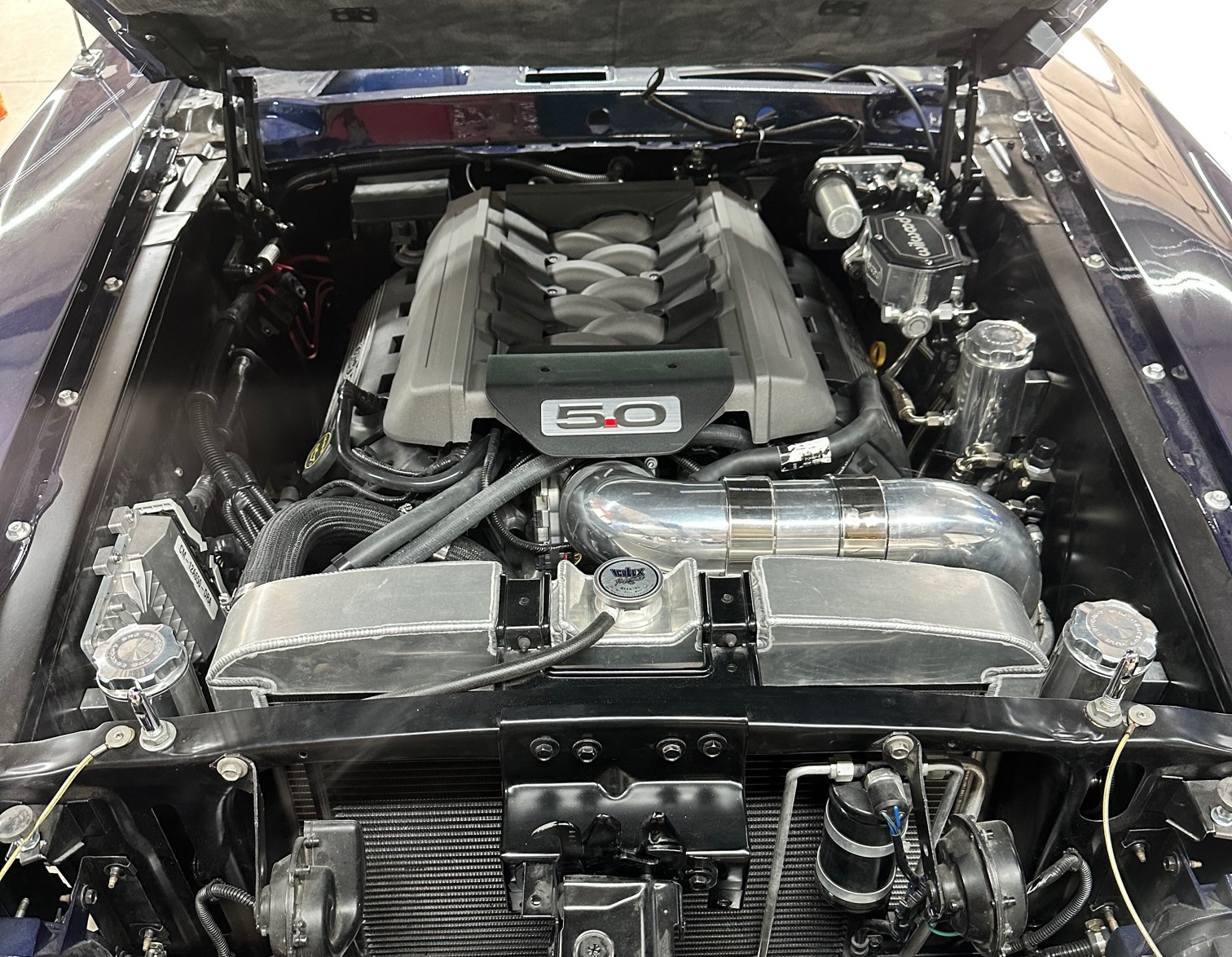

Hydroboost Unit Installed by a Customer in the 69/70 Engine Compartment with 5.0 Coyote Engine Installation Complete. Notice the clearances between the engine head and the Hydroboost Unit with the Cantilever bracket installed.

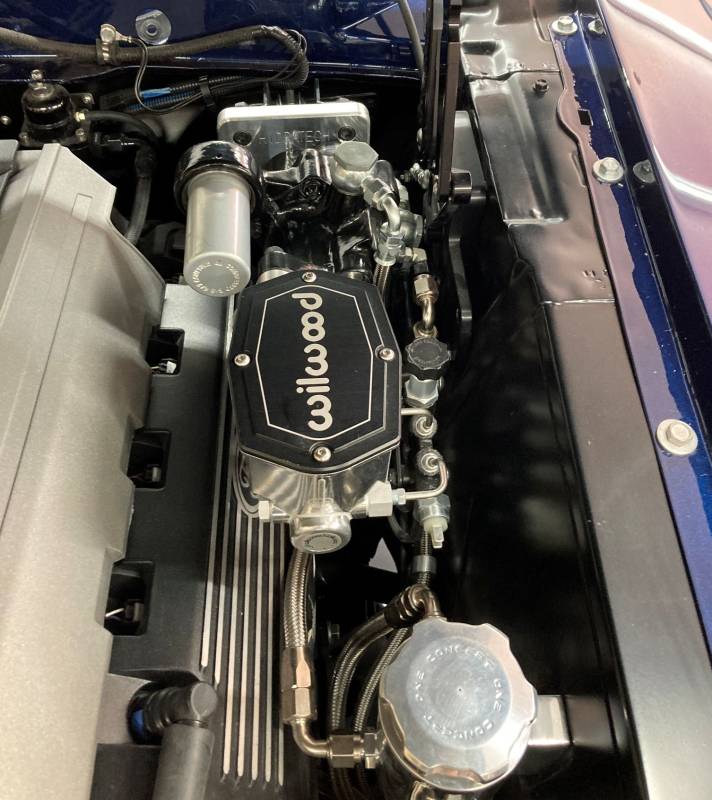

Close-up of the Same Car shown above. The customer routed the lines and plumbing to best fit with their master cylinder, and customer supplied the Remote P/S Fluid reservoir.

Another Install by a customer in a different Mustang. The unit fits nicely with the Coyote engine dimensions and clears the driver's side head. Notice the billet hood hinges for additional clearances.

You must login to post comments.